The heart of any great car audio system lies not just in expensive speakers or powerful amplifiers but in the quality of connections between components. Crimp connectors might seem insignificant compared to flashier audio equipment, but experienced installers know they can make or break your entire setup.

Poor connections lead to signal loss, noise introduction, and potential system failure—especially with the vibration and temperature variations typical in automotive environments. Quality crimp connectors ensure reliable electrical connections that maintain signal integrity and prevent system degradation over time.

This guide examines the best car audio crimp connectors set available today, helping you choose the right product for your installation needs. We’ll explore each option’s strengths and weaknesses, looking at durability, connection quality, ease of use, and value for money.

Contents

- What to Look for in Car Audio Crimp Connectors

- Top 5 Car Audio Crimp Connector Sets Reviewed

- Installation Guide: Getting the Most from Your Crimp Connectors

- Comparison Chart: Finding Your Perfect Connector Kit

- Application Guide: Matching Connectors to Installation Needs

- Troubleshooting: Fixing Common Connection Problems

- Advanced Tips for Professional Results

- Emerging Trends in Connection Technology

- Conclusion: Selecting the Right Connector System for Your Needs

- FAQ: Common Questions About Car Audio Crimp Connectors

What to Look for in Car Audio Crimp Connectors

Before diving into specific products, let’s discuss the key factors that separate quality connectors from subpar options:

Material Quality

The best crimp connectors use high-conductivity metals like copper or brass with protective plating (typically tin, nickel, or gold). Look for connectors with:

- Oxygen-free copper construction

- Corrosion-resistant plating

- Adequate metal thickness for current demands

Insulation Type

Quality insulation prevents shorts and withstands automotive temperature extremes:

- Nylon insulation offers good basic protection

- Heat shrink with adhesive provides superior waterproofing

- PVC covers work for non-critical applications

Connection Types

Different audio installations require various connector styles:

- Butt connectors join two wire ends inline

- Ring terminals connect wires to posts or screws

- Spade/fork terminals allow easy connection/disconnection from screw terminals

- Quick disconnects (male/female pairs) enable convenient separation of components

- Bullet connectors create secure yet detachable connections

Size Range

Connector selection should accommodate all wire gauges in your system:

- Power wiring typically requires 4-8 AWG connectors

- Signal wiring often uses 16-22 AWG connectors

- Speaker wiring usually needs 12-16 AWG connectors

Installation Tools

Consider whether specialized crimping tools are required:

- Some connectors work with basic pliers

- Others require specific crimpers for proper installation

- Heat shrink options need heat sources (heat gun or lighter)

Top 5 Car Audio Crimp Connector Sets Reviewed

Now let’s examine our five selected connector kits in detail:

1. TICONN 120Pcs Heat Shrink Wire Connectors Kit

Key Specifications:

- 120-piece assortment

- Heat shrink waterproof design

- Includes ring, fork, spade, and butt splices

- Marine-grade construction

Performance Analysis

TICONN’s heat shrink connector kit stands out for automotive applications where moisture resistance matters. The built-in sealant activates during heating to create waterproof connections that prevent corrosion—crucial for door speakers, trunk installations, or exposed connections.

These connectors use tinned copper construction with a thick heat shrink covering that includes adhesive lining. When properly heated, the adhesive melts and seals around the wire and connector, creating an environmental barrier that keeps moisture out and maintains connection integrity.

The kit provides good variety with ring terminals in various sizes, fork connectors for amplifier terminals, straight butt connectors for extending wires, and spade terminals for component connections. This selection covers most car audio installation needs.

The heat shrink process takes extra time but delivers superior long-term reliability compared to standard connectors. You’ll need a heat gun or lighter to properly activate the sealant and shrink the insulation around connections.

Pros:

- Exceptional water and corrosion resistance

- Adhesive liner creates complete environmental seal

- High-quality tinned copper construction

- Good variety of connector types

- Sturdy transparent storage case

Cons:

- Requires heat gun for proper installation

- Higher price point than basic connectors

- Limited quantity (120 pieces) may require additional purchases for larger projects

Best Used For:

This kit excels for permanent installations in moisture-prone areas like door panels, external amplifiers, or boats. The waterproof design makes these connectors ideal for any connection that might be exposed to condensation or occasional water contact.

User Experience

Car audio enthusiasts praise these connectors for their durability in challenging environments. Many users report these connections remaining intact and corrosion-free for years, even in humid climates or convertible vehicles where moisture exposure occurs regularly.

Professional installers often recommend this style of connector for critical power connections where reliability concerns outweigh installation convenience. The extra installation time pays dividends in reduced service calls and system longevity.

2. Kuject 320PCS Heat Shrink Wire Connectors Kit

Key Specifications:

- 320-piece comprehensive assortment

- Waterproof heat shrink design

- Multiple terminal types including rings, forks, spades, and butts

- Color-coded by wire size

Performance Analysis

The Kuject kit provides exceptional value with its 320-piece count, offering nearly three times the connectors of the TICONN kit at a competitive price point. This quantity makes it suitable for multiple installation projects or shops handling various vehicles.

Like the TICONN connectors, these feature heat-activated adhesive liners that create waterproof seals around wires. The connectors use copper construction with tin plating to resist corrosion, important for maintaining low-resistance connections in audio systems.

This kit stands out for its thoughtful organization, with color-coded connectors that help identify appropriate wire gauges quickly. Red connectors handle 22-16AWG wire, blue fits 16-14AWG, and yellow accommodates 12-10AWG—covering everything from delicate signal wires to power connections.

The variety impresses, including multiple ring terminal sizes for different stud diameters, several fork connector widths, and butt connectors for wire-to-wire connections. This diversity makes the kit versatile for complete system installations.

Pros:

- Excellent value—high piece count for the price

- Comprehensive selection covers virtually all connection needs

- Color-coded by wire gauge for easy identification

- Quality waterproof construction with adhesive liner

- Well-organized storage case with labeled compartments

Cons:

- Heat gun required for proper installation

- Some users report inconsistent adhesive quality in certain batches

- Larger storage case takes up more space in tool bags

Best Used For:

The Kuject kit shines for complete audio system installations or shops performing multiple installations. The quantity and variety make it ideal as a primary connector kit that can handle everything from head unit wiring to amplifier installations and speaker connections.

User Experience

DIY installers particularly appreciate this kit for its comprehensive nature—many report completing entire system installations without needing additional connectors. The color coding receives consistent praise for making wire gauge matching intuitive, reducing installation errors.

Some users note the heat shrink tubing requires higher temperatures than competing products to properly shrink and activate the adhesive. Using a heat gun rather than a lighter generally produces better results with these connectors.

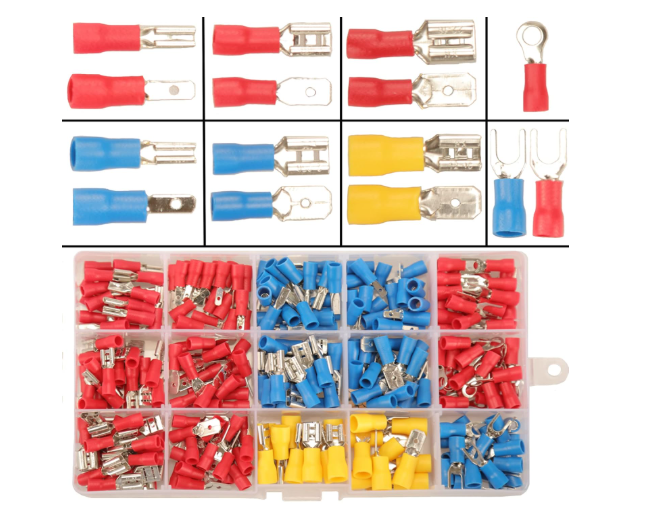

3. 280PCS Crimp Connectors, 2.8mm/4.8mm/6.3mm Male and Female Spade Connector Kit

Key Specifications:

- 280-piece spade connector focus

- Multiple sizes: 2.8mm, 4.8mm, and 6.3mm

- Includes male and female pairs

- 15 connector types including rings and forks

- Non-heat shrink design

Performance Analysis

This connector kit differs significantly from our first two options by focusing on quick-disconnect spade terminals rather than heat shrink products. This design philosophy prioritizes serviceability—allowing components to be disconnected for troubleshooting or upgrades without cutting wires.

The kit features brass construction with tin plating for good conductivity and reasonable corrosion resistance. The insulation uses colored nylon that’s durable but not waterproof like heat shrink options. This makes these connectors better suited for interior installations away from moisture.

The three size options (2.8mm, 4.8mm, and 6.3mm) correspond to different current-carrying capacities, with the larger 6.3mm connectors handling power connections while smaller sizes work for signal and speaker connections. The male/female pairing allows for creating disconnect points throughout the system.

Installation proves faster than heat shrink options since these require only a crimping tool without heating. The trade-off comes in moisture resistance and long-term durability in high-vibration environments.

Pros:

- Quick installation without heat required

- Creates serviceable connections that can be disconnected later

- Multiple size options for different current requirements

- Good variety of terminal types

- Cost-effective solution

Cons:

- Limited moisture resistance compared to heat shrink options

- May loosen over time in high-vibration environments

- Requires careful matching of male/female connector sizes

- Storage case quality below average

Best Used For:

These connectors work best for interior installations where components might need future service or replacement. They’re ideal for connecting head units, creating disconnect points for removable components, or temporary installations where heat shrink permanence isn’t desired.

User Experience

Users who frequently modify their systems particularly value these connectors. The ability to disconnect components without cutting wires makes troubleshooting and upgrades significantly easier. Many report creating strategic disconnect points at amplifiers, processors, and crossovers using these connectors.

Some users note that the crimping must be done carefully to achieve secure connections. Using the correct crimping tool rather than standard pliers significantly improves connection quality and long-term reliability with these connectors.

4. Nilight – 50036R Closed End Crimp Terminal 300 pcs

Key Specifications:

- 300-piece closed-end connector focus

- Three size ranges: 22-16/16-14/12-10 gauge

- Nylon insulated caps

- Color-coded by wire size

- Two-year warranty

Performance Analysis

The Nilight 50036R kit specializes in closed-end crimp connectors, also called “caps” or “end-stops.” These connectors serve specific but important functions in car audio installations: securing unused wires, creating wire branches, and connecting multiple small wires into a single circuit.

These connectors feature vinyl insulation caps that cover the entire crimp area, providing good electrical isolation but limited waterproofing. The metal portions use tinned copper for good conductivity and reasonable corrosion resistance when kept dry.

The kit includes three wire gauge ranges with color coding: red (22-16 AWG), blue (16-14 AWG), and yellow (12-10 AWG). This covers most car audio wiring needs from signal wires to moderate power connections. The connector design allows inserting wires from one end only, with the opposite end sealed.

Installation requires a crimping tool but demands less precision than open-ended connectors since the closed design naturally aligns wires. The vinyl caps provide strain relief that helps connections withstand vibration—important in automotive environments.

Pros:

- Perfect for terminating unused wires safely

- Excellent for creating parallel connections or “taps”

- Color-coded for easy wire gauge identification

- Good quantity provides ample connectors for large projects

- Two-year warranty shows manufacturer confidence

Cons:

- Limited to specific wire termination applications

- Not suitable for main connections between components

- Minimal moisture protection compared to heat shrink

- Requires specific crimping technique for secure connections

Best Used For:

These closed-end connectors excel for creating branch circuits (like adding multiple tweeters to a single channel), capping unused wires safely, or making parallel connections without cutting main wires. They’re particularly useful when adding aftermarket components to factory wiring where preserving original connections matters.

User Experience

Installers particularly value these connectors when integrating new components with factory wiring. The ability to create branches without cutting original wires allows for non-destructive installations that can be returned to stock if needed.

Several users note these connectors work well for creating distribution points for LED lighting or other accessories that run off the same power source. The closed-end design prevents short circuits more effectively than electrical tape or basic wire nuts.

The two-year warranty receives positive mentions from users who experienced responsive customer service when addressing quality concerns in previous batches. This warranty length exceeds industry standards for connector products.

5. Nilight 540PCS Mixed Quick Disconnect Electrical Connector Kit

Key Specifications:

- 540-piece comprehensive assortment

- Includes bullets, spades, rings, and butt connectors

- Non-insulated and insulated options

- Color-coded by wire size

- Storage case with labeled sections

Performance Analysis

The Nilight 540-piece kit stands as the most comprehensive option in our lineup, offering an impressive variety of connector types in a single package. With over 500 pieces, this kit suits professional installers or serious DIYers tackling multiple vehicles or complex installations.

This kit incorporates multiple connector philosophies, including quick disconnects (bullets and spades), permanent connections (butt connectors), terminal connections (rings and forks), and specialized options. This diversity makes it extremely versatile for different installation approaches.

Most connectors feature vinyl or nylon insulation in color-coded formats: red for 22-16AWG, blue for 16-14AWG, and yellow for 12-10AWG. Some connectors are uninsulated, allowing custom heat shrink application where needed. The metal components use tinned copper for good electrical performance.

Unlike specialized waterproof kits, these standard connectors install quickly with basic crimping tools without requiring heat guns or other equipment. This speeds installation but sacrifices some environmental protection compared to heat shrink options.

Pros:

- Exceptional variety covers virtually every connection type

- Outstanding value considering piece count and diversity

- Good quality materials with appropriate strain relief

- Logical organization in durable storage case

- Suitable for multiple complete installations

Cons:

- Standard insulation lacks moisture protection of heat shrink options

- Quality slightly below specialized kits for specific connector types

- Some compartments mix connector types, complicating selection

- Case size substantial—takes significant storage space

Best Used For:

This kit serves as an excellent general-purpose solution for installers who work on various vehicles or those wanting maximum flexibility. The variety makes it particularly valuable for complex installations with multiple connection types or when the specific needs aren’t known in advance.

User Experience

Professional installers frequently praise this kit as a “go-to” option that handles most installation scenarios without needing supplemental connectors. Many report carrying this as their primary connector solution in mobile installation businesses.

DIY users appreciate the kit’s comprehensiveness, noting they rarely need additional connectors even for complex installations. The variety allows experimentation with different connection approaches to find what works best for specific vehicles and components.

Some users report the case organization could be improved, with occasional mixing of different connector types in shared compartments. Many solve this by reorganizing into custom storage solutions after purchase.

Installation Guide: Getting the Most from Your Crimp Connectors

Proper installation technique dramatically affects connection quality and longevity. Follow these guidelines to achieve professional results:

Tools You’ll Need

For basic crimp connections:

- Quality crimping tool (ratcheting style preferred)

- Wire strippers with gauge indicators

- Diagonal cutters for trimming wire

- Small files for deburring cut wire ends

For heat shrink connections, add:

- Heat gun (preferred) or butane lighter

- Heat resistant work surface

Step-by-Step Installation Process

- Select the correct connector size based on wire gauge and terminal requirements.

- Strip wire insulation carefully—remove enough to fill the connector barrel without exposing wire beyond the connector.

- Prepare the wire by twisting stranded conductors and checking for clean cuts without frayed strands.

- Insert wire fully into the connector barrel, ensuring no insulation enters the crimp zone.

- Position crimping tool correctly:

- For non-insulated connectors: Crimp the metal barrel first

- For insulated connectors: Position tool over appropriate locations marked on connectors

- Apply even pressure until crimping tool fully cycles (ratcheting tools) or appropriate compression is achieved.

- Test connection strength with a gentle tug—wire should remain firmly attached.

- For heat shrink connectors:

- Apply heat evenly around the entire connector

- Rotate to ensure uniform heating

- Continue until shrink tubing contracts fully and adhesive visibly flows

- Allow cooling before manipulating heat shrink connections.

- Test completed connections before final installation in vehicle.

Common Installation Mistakes

- Insufficient stripping: Too little exposed wire creates weak connections

- Excessive stripping: Too much exposed wire risks shorts or breaks

- Wrong size connector: Using incorrect gauge connectors causes loose fits or damaged wire

- Improper crimping pressure: Too light fails to secure wire, too heavy can break connector

- Insufficient heat: Heat shrink tubing needs complete shrinkage to seal properly

- Rushed cooling: Manipulating hot connections can break adhesive seals

Comparison Chart: Finding Your Perfect Connector Kit

| Feature | TICONN 120Pcs | Kuject 320PCS | 280PCS Spade Kit | Nilight 50036R | Nilight 540PCS |

|---|---|---|---|---|---|

| Piece Count | 120 | 320 | 280 | 300 | 540 |

| Waterproof | Yes (heat shrink) | Yes (heat shrink) | No | No | No |

| Wire Range | 10-22 AWG | 10-22 AWG | 12-22 AWG | 10-22 AWG | 10-22 AWG |

| Primary Types | Mixed | Mixed | Spade/Quick Disconnect | Closed End | Comprehensive |

| Installation | Heat Required | Heat Required | Crimp Only | Crimp Only | Crimp Only |

| Best For | Water Resistance | Complete Installs | Serviceable Systems | Wire Branching | Versatility |

Application Guide: Matching Connectors to Installation Needs

Different audio system components have specific connector requirements:

Head Unit Connections

- Recommended: Quick disconnect spades (280PCS Spade Kit or Nilight 540PCS)

- Why: Allows head unit removal without cutting wires

- Installation tip: Create a wiring harness with labeled connections

Amplifier Power Wiring

- Recommended: Heat shrink ring terminals (TICONN or Kuject)

- Why: Secure, waterproof connection for high-current applications

- Installation tip: Use appropriate gauge rings for amplifier terminals

Speaker Connections

- Recommended: Butt connectors or quick disconnects based on access needs

- Why: Speakers often need service or replacement

- Installation tip: Leave service loops with extra wire length

Signal Cables (RCA alternatives)

- Recommended: Small gauge bullet connectors or butt connections

- Why: Maintains signal integrity with secure connections

- Installation tip: Keep signal wires separated from power cables

Distribution Blocks and Fuse Holders

- Recommended: Heat shrink ring terminals (TICONN or Kuject)

- Why: Critical safety connections benefit from waterproof reliability

- Installation tip: Use appropriate ring size for terminal posts

Troubleshooting: Fixing Common Connection Problems

Even with quality connectors, issues can arise. Here’s how to diagnose and fix common problems:

Intermittent Sound

Possible causes:

- Loose crimp connection

- Corroded connector

- Wire strand breakage inside connector

Solutions:

- Redo connection with proper crimping technique

- Inspect for corrosion and replace affected connectors

- Use strain relief to prevent wire fatigue

Power Loss or Voltage Drop

Possible causes:

- Undersized connector for current demands

- High-resistance connection from poor crimp

- Oxidation at connection points

Solutions:

- Replace with larger gauge connector

- Ensure full crimping compression

- Use conductive grease on terminal connections

Ground Loop Noise

Possible causes:

- Multiple ground paths through different connectors

- Poor shield connections in signal wiring

- Ground connections with different resistance

Solutions:

- Standardize ground connector types

- Use shielded wire with proper shield connections

- Create star grounding configuration

Connection Overheating

Possible causes:

- Undersized connector for current flow

- Loose connection creating resistance

- Oxidation building resistance

Solutions:

- Upgrade to larger connector

- Redo connection with proper technique

- Clean terminal surfaces before connection

Advanced Tips for Professional Results

Take your installation to the next level with these professional techniques:

Creating Custom Connector Assemblies

Combine different connector types to create specialized solutions:

- Use heat shrink tubing over standard connectors for added protection

- Create Y-adapters with multiple connectors for distribution points

- Build quick-disconnect harnesses for removable components

Specialized Applications

Marine Audio Installations:

- Use exclusively heat shrink connectors with adhesive

- Add dielectric grease to connections before crimping

- Consider double heat shrinking critical connections

Competition Audio Systems:

- Use oversized connectors for power connections

- Create distribution blocks with multiple ring terminals

- Implement redundant ground connections with parallel terminals

Daily Driver Installations:

- Focus on serviceability with quick disconnects at strategic points

- Use closed-end connectors for security system integration

- Implement strain relief at all connection points

Aesthetic Improvements

- Use color-coded connectors to create easily traced circuits

- Implement consistent connector orientation for professional appearance

- Add clear heat shrink over colored connectors for customized look

Emerging Trends in Connection Technology

The car audio connection market continues evolving with these emerging trends:

Solderless Technologies

New connector designs aim to provide solder-quality connections without heat:

- Compression fittings with specialized tools

- Ultra-sonic welded connections

- Spring-loaded constant pressure terminals

Smart Connectors

Some high-end systems now incorporate diagnostic capabilities:

- Temperature-sensing connectors for safety monitoring

- Current-measuring terminals for system optimization

- Connection quality monitoring through resistance testing

Environmental Protection Advances

Beyond basic heat shrink:

- Connectors with integrated environmental seals

- Marine-grade options with multi-layer protection

- Oxygen-barrier technologies that prevent corrosion

Conclusion: Selecting the Right Connector System for Your Needs

After examining the top five car audio crimp connector kits, clear patterns emerge that can guide your selection:

For maximum durability in challenging environments, the TICONN and Kuject heat shrink kits provide superior moisture protection and long-term reliability. These shine in permanent installations where connections rarely need service.

For serviceability and systems requiring frequent changes, the 280PCS Spade Connector Kit offers convenient disconnect points throughout your system, though with some compromise in environmental protection.

For specialized applications like adding components to factory wiring, the Nilight 50036R closed-end terminals provide safe wire termination and branching options not found in other kits.

For maximum versatility across multiple installations, the Nilight 540PCS comprehensive kit offers unmatched variety, making it ideal as a complete solution for installers working on various vehicles.

Your ideal choice depends on your specific needs:

- First-time installers often benefit from the Kuject kit’s comprehensive nature and clear color-coding

- Professional installers typically prefer either the Nilight 540PCS for variety or specialized kits for specific applications

- Marine audio installers should prioritize the waterproof options from TICONN or Kuject

- Competition builders often combine multiple kits for specialized applications throughout their systems

Whatever your choice, quality connectors represent a small investment that yields significant returns in system reliability, performance, and longevity. Cutting corners on connections often leads to frustrating troubleshooting and rework later—making proper connectors a wise investment for any audio enthusiast.

FAQ: Common Questions About Car Audio Crimp Connectors

Q: Can I reuse crimp connectors? A: Generally no. Crimp connectors are designed for one-time use. Removing and recrimping typically results in unreliable connections. For serviceable points, use quick disconnect connectors instead.

Q: Do I really need a special crimping tool? A: Yes. While pliers can physically compress connectors, proper crimping tools create uniform pressure that maintains wire integrity and connection strength. Ratcheting crimpers ensure consistent compression across all connections.

Q: Are waterproof connectors necessary for interior installations? A: While not strictly necessary, waterproof connectors still offer advantages for interior use. They provide better vibration resistance and protect against occasional spills, window leaks, and condensation that can occur in vehicle interiors.

Q: How do I know what wire gauge I’m working with? A: Use a wire gauge tool or the gauge markers on quality wire strippers. Alternatively, compare to known reference wires: power wires are typically 4-8 AWG, speaker wires usually 12-16 AWG, and signal wires commonly 18-22 AWG.

Q: Can I mix brands of connectors and crimping tools? A: Yes, but with caution. Different manufacturers may use slightly different dimensions. Test compatibility on spare connectors before committing to critical connections. Ratcheting crimpers with adjustable pressure work best across different brands.

Q: How long should car audio connections last? A: Quality connections using appropriate connectors should last the vehicle’s lifetime. Heat shrink connections often remain viable for 10+ years, while standard insulated connectors might require inspection and occasional replacement after 3-5 years in high-vibration environments.